Taper Roller Bearings

Taper Roller Bearings Specification

- Size

- Customized, standard sizes available

- Model

- Taper Roller Series (30200, 30300, 32000, etc.)

- Lubrication Type

- Grease or oil lubricated

- Bore Size

- 20 mm to 160 mm

- Sealed Type

- Open or double-shielded

- Surface Treatment

- Anti-corrosive coating

- Material

- High-grade chrome steel (GCr15)

- Grease

- Lithium-based bearing grease recommended

- Application

- Gearboxes, wheel hubs, transmissions, differential units

- Usage

- Automobile, industrial machinery, heavy vehicles

- Basic Dimensions (mm)

- Bore (d): 20-160, Outer (D): 47-300, Width (B/T): 14-75

- Mass

- Varies as per model (typical: 0.2 kg - 3 kg)

- Car Make

- Universal

- Noise Level

- Low

- Vibration Level

- Low

- Cage Type

- Steel, Brass

- Operating Temperature Range

- -40°C to 120°C

- Load Rating

- High radial and axial load-carrying capacity

- Compliance

- ISO 9001:2015 Certified

- Rolling Elements

- Tapered rollers

- Hardness

- HRC 58-64

- Precision Rating

- P0, P6, P5 as per standard

Taper Roller Bearings Trade Information

- Main Domestic Market

- South India

About Taper Roller Bearings

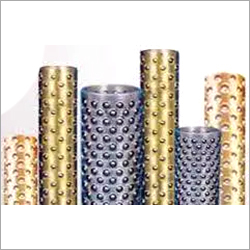

Owing to our expertise, we are the manufacturer and supplier of a wide gamut of Taper Roller Bearings. These roller bearings are manufactured in our advance manufacturing unit by our professionals using supreme grade raw material with advanced tools and techniques. Provided roller bearings are used in vehicles and industrial devices for carrying both large radial as well as thrust loads. Offered bearings are also analyzed on several parameters by our quality controllers to ensure their perfection. Our precious clients can avail these Tapered Roller Bearings at reasonable price from us.

Features:

-

Anti-corrosive

-

Excellent durability

-

Easy to fit

-

High strength

Engineered for Versatility and High Load

These taper roller bearings accommodate both radial and axial loads, making them suitable for demanding environments such as automobiles, gearboxes, and heavy industrial machinery. Their universal application ensures compatibility across various car makes and industrial designs.

Superior Durability and Material Quality

Manufactured from high-grade chrome steel (GCr15) and crafted with precision, these bearings offer a hardness level between HRC 58-64 and are protected by an anti-corrosive coating. The steel or brass cage further enhances strength and longevity in challenging conditions.

Certified Quality and Low Maintenance

Adhering to ISO 9001:2015 standards, these bearings guarantee consistent quality and performance. Their low vibration and noise levels minimize operational disruption, while recommended lithium-based bearing grease helps extend bearing life for both sealed and open types.

FAQs of Taper Roller Bearings:

Q: How do I select the right taper roller bearing size for my application?

A: Choosing the appropriate taper roller bearing depends on the required bore diameter, outer diameter, width, and load capacity. Standard sizes range from 20 mm to 160 mm for the bore, but customized sizes are also available to match specific requirements.Q: What are the primary benefits of using these taper roller bearings in industrial machinery?

A: These bearings provide high radial and axial load-carrying capacity, low vibration, and low noise operation. Their robust construction and anti-corrosive coating ensure reliability and durability, essential for industrial environments and heavy-duty equipment.Q: When is it recommended to use lithium-based bearing grease with these bearings?

A: Lithium-based bearing grease is recommended during installation and routine maintenance to ensure optimal lubrication, reduce friction, prevent wear, and extend bearing service life. For high-speed or high-temperature applications, proper lubrication is particularly crucial.Q: Where can these taper roller bearings be used?

A: They are widely used in automotive wheel hubs, gearboxes, transmission assemblies, and industrial machinery, as well as in differential units. Their universal design makes them suitable for various car models and heavy vehicles.Q: What is the process for installing a taper roller bearing?

A: Begin by cleaning the housing and shaft, apply the recommended grease, and gently tap the bearing into place using the correct tools. Ensure proper alignment, check for a snug fit, and avoid applying excessive force that could damage the rollers or cage.Q: How does ISO 9001:2015 certification benefit customers?

A: ISO 9001:2015 certification ensures that the bearings are produced under strict quality management processes, providing customers with confidence in product consistency, reliability, and performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Ball Bearings Category

Needle Roller Bearing

Minimum Order Quantity : 1 Piece

Car Make : Universal/Application Specific

Size : Customizable/As Required

Model : Standard Needle Roller

Usage : Other, Automotive and Industrial Machinery

Lubrication Type : Greased or Oil Lubricated

Ball Cage Bearing

Minimum Order Quantity : 6 Pieces

Car Make : Universal

Size : Available in multiple sizes as per requirement

Model : Standard/Custom

Usage : Other, Industrial machinery, automotive applications, and precision equipment

Lubrication Type : Grease or oil lubricated

Angular contact bearings

Minimum Order Quantity : 2 Pieces

Car Make : Compatible with a variety of industrial and automotive models; consult manufacturer for specifics.

Size : Customizable as per application; refer to basic dimensions for common sizes.

Model : Variety available, e.g., 7204, 7206, 7310, 7312 depending on required specification.

Usage : Other, Used in applications demanding high precision and combined radial and axial loads such as machine tools, pumps, gearboxes, and electric motors.

Lubrication Type : Grease or oil lubrication, based on application requirements.

Cylindrical Roller Bearings

Minimum Order Quantity : 2 Pieces

Car Make : Universal/Applicable for various brands

Size : Varies by type and model

Model : Cylindrical Roller Bearings Series NU/NJ/NUP/N

Usage : Other, Industrial Machinery, Automotive, Heavy Equipment

Lubrication Type : Grease or Oil lubricated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free